Production Process of Graphite Electrodes

Graphite electrodes are produced using petroleum coke and needle coke as aggregates and coal tar pitch as a binder, through a series of processes such as kneading, molding, baking, impregnation, graphitization, and machining. Graphite electrodes are important high-temperature conductive materials for electric arc furnace steelmaking. Electrical energy is input into the electric arc furnace through graphite electrodes, and the high temperature generated by the arc between the electrode tip and the charge is used as a heat source to melt the charge for steelmaking.

Raw materials

Petroleum coke and needle coke

Crushing, screening, and batching

Before adding ingredients, the large pieces of calcined petroleum coke and needle coke must be crushed, ground, and sieved. Then, according to the formula requirements, the various particle sizes of aggregates and powders, and binders are calculated, weighed, and batched.

Kneading

The process of uniformly mixing a certain quantity of carbonaceous particles and powder of various particle sizes with a certain quantity of coal tar pitch binder at a certain temperature to form a plastic paste.

Forming

The process of shaping a mixed carbon paste into a green body with a certain shape, size, density, and strength through plastic deformation under the external force applied by the forming equipment.

Baking

This is a process where a green carbon product is heat-treated at high temperatures in a specially designed furnace with filler protection, carbonizing the coal tar pitch in the green body. After baking, the carbon product has high mechanical strength, low resistivity, and good thermal and chemical stability.

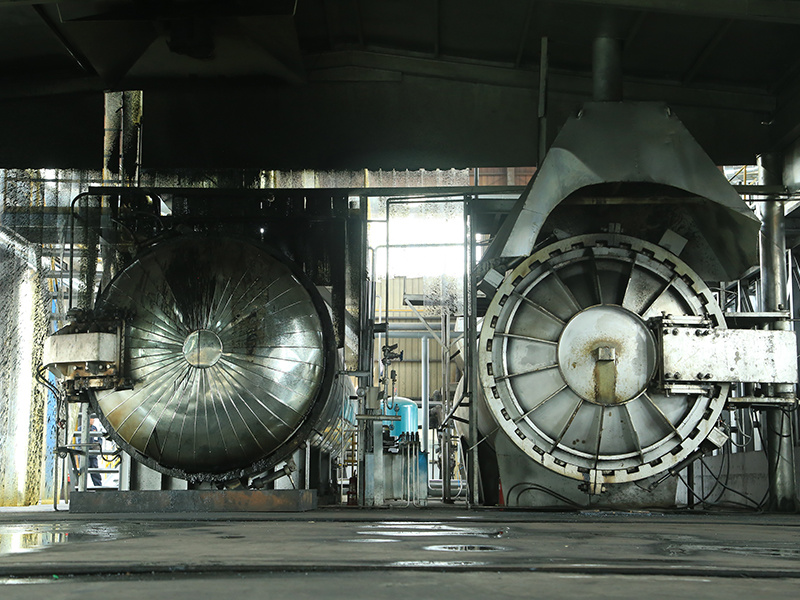

Impregnation with bitumen

The process of impregnating a carbon material placed in a pressure vessel with a liquid asphalt impregnant under certain temperature and pressure conditions to penetrate the pores of the product electrode. The purpose is to reduce the porosity of the product, increase the bulk density and mechanical strength of the product, and improve the electrical conductivity and thermal conductivity of the product.

Secondary baking

Electrodes (excluding RP) and connector blanks that require high production bulk density must undergo a second firing; connector blanks also require three impregnations and four firings or two impregnations and three firings.

Graphitization

The purpose of graphitization is to improve the product's conductivity and thermal conductivity, enhance its impact resistance and chemical stability, and impart lubricity and wear resistance, while removing impurities and increasing purity. RP electrodes require a graphitization temperature range of 2500-2600 degrees, with a resistivity of 8.5 or less; HP electrodes require a graphitization temperature range of 2600-2800 degrees, with a resistivity of 6.0 or less; UHP electrodes require a graphitization temperature of 2800 degrees or higher, with a resistivity of 5.8 or less.

Quality inspection

Samples of each batch of graphitized graphite electrodes and connectors are sent to the laboratory for testing of resistivity, flexural strength, elastic modulus, bulk density, and thermal expansion coefficient to ensure that the products meet quality requirements.

Machining

The purpose is to use cutting processing to achieve the required size, shape, precision, etc., to produce the electrode body and connector that meet the usage requirements. Graphite electrode processing is divided into two independent processing processes: the electrode body and the connector.

Finished product and packing inspection

Includes inspection of finished product appearance, weight, length, diameter, resistivity, and volume density; packaging inspection, checking small labels and shipping marks for correctness and packaging frame sturdiness according to customer requirements.

Download